English

English-

English

English -

Español

Español -

Português

Português -

русский

русский -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski

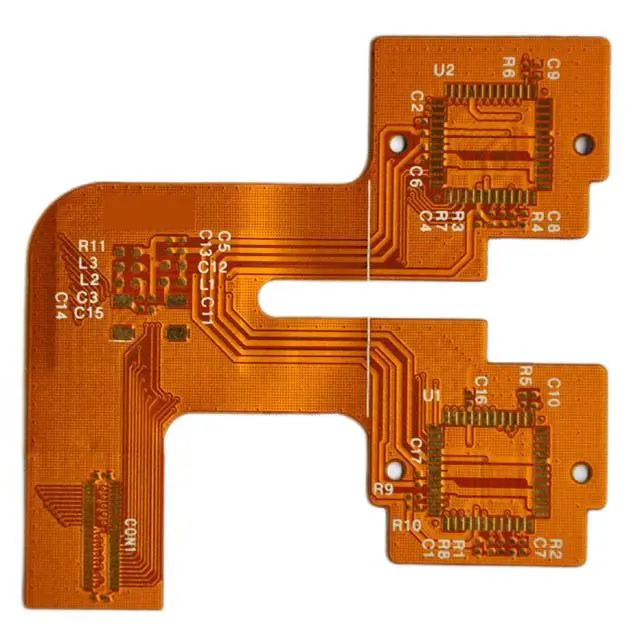

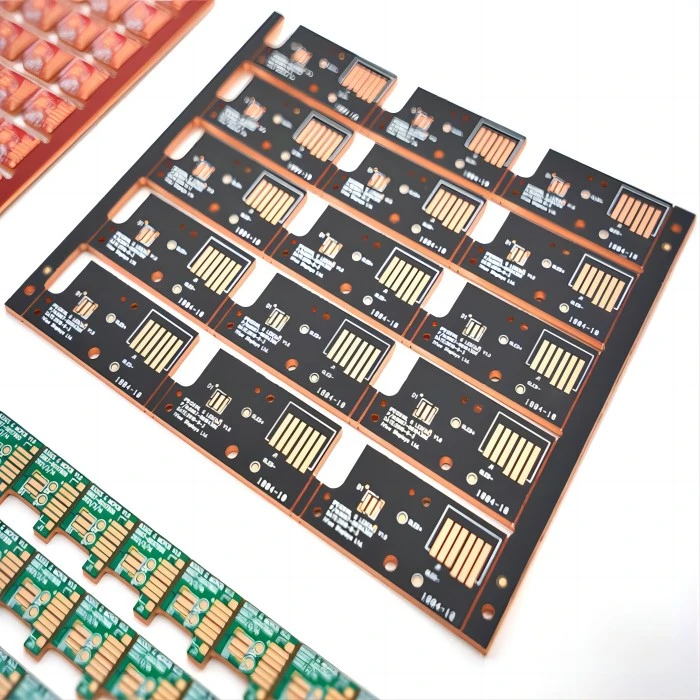

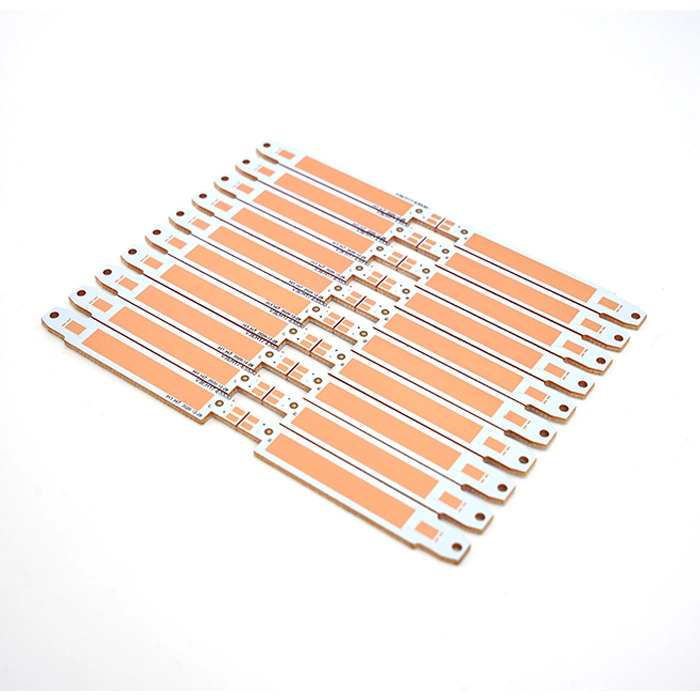

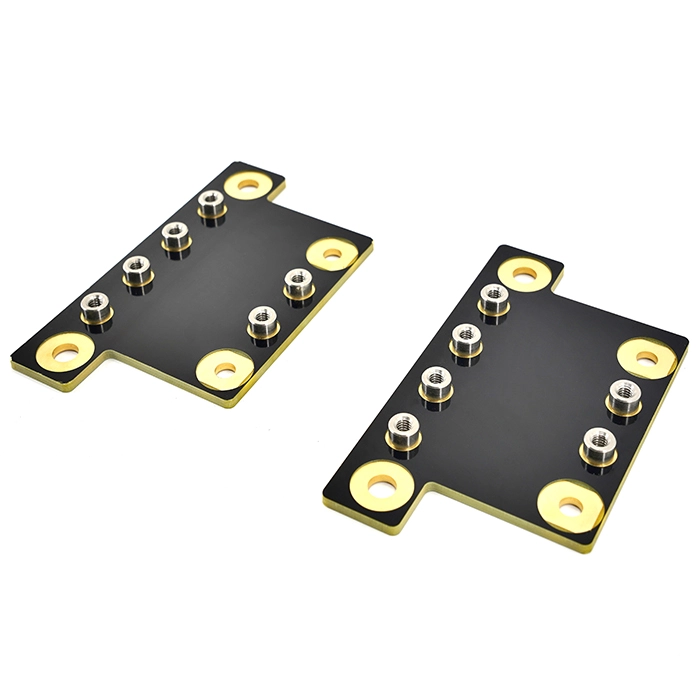

Rigid Flex PCB

JBPCB is a Rigid Flex Pcb manufacturer from Shenzhen, China. We have reached strategic cooperation with more than 10,000 high-tech R&D and manufacturing companies around the world. Our PCB has passed ISO9001 quality system certification, IATF16949 certification in the automotive industry, UL certification in the United States, and SGS certification. If you want to customize rigid-flex PCB, please contact us and get our factory quotation.

Send Inquiry

Product Description

Rigid-flex PCB Product Introduction:

You can rest assured to buy Rigid Flex Pcb from our factory and we will offer you the best after-sale service and timely delivery. Rigid-flex PCB is also a combination PCB with soft and hard coating.

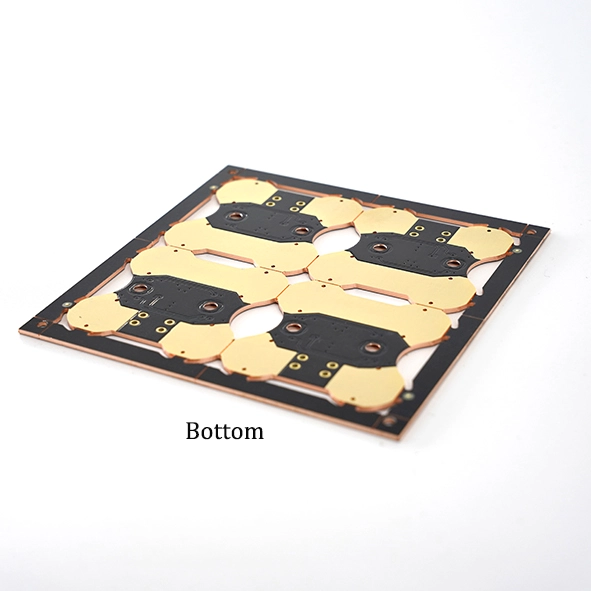

A rigid-flex board is a combination of rigid and flexible board, which is a printed circuit board formed by combining a thin layer of a flexible bottom layer and a rigid bottom layer , and then laminating them into a component.

Flexible-rigid printed circuit boards are printed circuit boards that combine the technologies of flexible and rigid printed circuit boards. Most rigid-flex printed circuit boards consist of several layers of flexible circuit substrates that are externally and/or internally bonded to one or more rigid circuit boards, depending on the application design. Flexible substrates are designed to flex permanently and are usually formed into a flex curve during manufacture or installation.

Traditional rigid-flex PCB consist of rigid and flexible substrates selectively laminated to each other. The structure is hermetic, metallization L forms a conductive connection. If the PCB has front and back components, the rigid-flex PCB is a kind of A good choice. But if all the components are on the same side, then it is more economical to use a double-sided flexible board with a layer of FR4 reinforcement laminated on the back side.

Rigid- Flex PCB design is more complex than the typical rigid board environment because the boards are designed in 3D space, which also provides greater space efficiency. With the ability to design flex- rigid circuit boards in 3D, it is possible to twist, fold, and roll the flex board substrate to achieve the shape required for the final packaging of the application.

Rigid-flex PCB offer a wide range of applications from smart devices to mobile phones and digital cameras. Rigid-flex PCB fabrication is increasingly being used in medical devices such as pacemakers to reduce their size and weight. The use of rigid-flex printed circuit boards has the same advantages and can be used in intelligent control systems.

In consumer products, flex-rigid PCB boards not only maximize space utilization and minimize weight, but also greatly improve reliability by eliminating many of the need for solder joints and fragile, fragile wiring that is prone to connection problems. These are just a few examples, but Rigid-Flex PCBs can be useful for almost all advanced electrical applications, including test equipment, tools, and automobiles.

A rigid-flex board is a combination of rigid and flexible board, which is a printed circuit board formed by combining a thin layer of a flexible bottom layer and a rigid bottom layer , and then laminating them into a component.

Flexible-rigid printed circuit boards are printed circuit boards that combine the technologies of flexible and rigid printed circuit boards. Most rigid-flex printed circuit boards consist of several layers of flexible circuit substrates that are externally and/or internally bonded to one or more rigid circuit boards, depending on the application design. Flexible substrates are designed to flex permanently and are usually formed into a flex curve during manufacture or installation.

Traditional rigid-flex PCB consist of rigid and flexible substrates selectively laminated to each other. The structure is hermetic, metallization L forms a conductive connection. If the PCB has front and back components, the rigid-flex PCB is a kind of A good choice. But if all the components are on the same side, then it is more economical to use a double-sided flexible board with a layer of FR4 reinforcement laminated on the back side.

Rigid- Flex PCB design is more complex than the typical rigid board environment because the boards are designed in 3D space, which also provides greater space efficiency. With the ability to design flex- rigid circuit boards in 3D, it is possible to twist, fold, and roll the flex board substrate to achieve the shape required for the final packaging of the application.

Rigid-flex PCB offer a wide range of applications from smart devices to mobile phones and digital cameras. Rigid-flex PCB fabrication is increasingly being used in medical devices such as pacemakers to reduce their size and weight. The use of rigid-flex printed circuit boards has the same advantages and can be used in intelligent control systems.

In consumer products, flex-rigid PCB boards not only maximize space utilization and minimize weight, but also greatly improve reliability by eliminating many of the need for solder joints and fragile, fragile wiring that is prone to connection problems. These are just a few examples, but Rigid-Flex PCBs can be useful for almost all advanced electrical applications, including test equipment, tools, and automobiles.

Rigid-flexible PCB Structure Diagram:

Diagram of The Anatomy of A Flexible-rigid Printed Circuit Board:

Instructions for Rigid-Flex PCB Fabrication and Production Process:

| material | FR4+FPC |

| Sheet thickness (mm) | 0.6 ~ 3.0mm |

| Minimum hole diameter ( mm) | 0.2 |

| Minimum line width and line spacing ( mil) | 2.5 |

| Copper Thickness (µm) | 35;70;105;140-350 |

| Solder mask color | white, black, matt black, red, green, blue, matt green |

| character color | white/black/orange/red/blue |

| molding method | CNC racing plate; CNC V-cutting; stamping; laser cutting and milling. |

| control test | AOI; high speed flying probe; electronic test; voltage test |

| Surface treatment process | HASL; Lead Free DNIG OSP |

|

delivery time |

6 ~ 8 days |

Fields of Application of Flexible-rigid Printed Circuit Boards:

Rigid PCB is a new type of PCB that has both the durability of a rigid PCB and the adaptability of a flexible PCB Among all PCB types, the combination of rigid and flexible is the most resistant to harsh environments.

a) Industrial use - Industrial use includes flexible rigid printed circuit boards used in industrial, military and medical applications . Most industrial parts require characteristics such as precision, safety, and damage resistance. Therefore, the characteristics required for rigid-flex PCBs are high reliability , high accuracy, low impedance loss, complete signal transmission quality, and durability. However, due to the high complexity of the process, the output is low and the unit price is rather high.

b) Mobile phone - Rigid-flex PCB application in mobile phone , hinges, camera module, keypad and RF module of foldable mobile phone are common. The advantages of using rigid-flex circuit boards in mobile phones are, firstly, the integration of components into the mobile phone and, secondly, the consideration of the amount of signal transmitted. At present, in mobile phone products , rigid-flex circuit boards are used to replace the original combination of two connectors and flexible circuit boards. These products are highly stable and highly appreciated. On the other hand, due to the popularity of camera phones and the integration of multimedia and IT functions into mobile phones, the transmission volume of the internal signal of mobile phones has increased, and accordingly, there has been a need for modularity.

c) Consumer electronic products. Among consumer products, DSC and DV represent the development of rigid-flex PCBs , which can be considered in two main areas: "performance" and "structure". In terms of performance, the rigid-flex PCB can connect various rigid boards and PCB components in 3D, so the total usable area of the PCB can be increased with the same line density, which can relatively improve its circuit design. capacitance, and reduce the contact signal transmission limit and assembly error rate difference. On the other hand, because the Rigid-Flex PCB is light and thin, it can bend the wiring, which has significant advantages in terms of size and weight reduction.

d) Automobile - the use of rigid-flex circuit board in automobiles , the commonly used buttons connected to the motherboard on the steering wheel, the connection between the car video system screen and the control panel, the working connection of the audio or function keys on the side door and the reverse radar image system, the sensor (including air quality, temperature and humidity, special gas control, etc.), vehicle communication system, satellite navigation, rear seat control panel and front controller connection board, vehicle appearance detection system. , etc.

a) Industrial use - Industrial use includes flexible rigid printed circuit boards used in industrial, military and medical applications . Most industrial parts require characteristics such as precision, safety, and damage resistance. Therefore, the characteristics required for rigid-flex PCBs are high reliability , high accuracy, low impedance loss, complete signal transmission quality, and durability. However, due to the high complexity of the process, the output is low and the unit price is rather high.

b) Mobile phone - Rigid-flex PCB application in mobile phone , hinges, camera module, keypad and RF module of foldable mobile phone are common. The advantages of using rigid-flex circuit boards in mobile phones are, firstly, the integration of components into the mobile phone and, secondly, the consideration of the amount of signal transmitted. At present, in mobile phone products , rigid-flex circuit boards are used to replace the original combination of two connectors and flexible circuit boards. These products are highly stable and highly appreciated. On the other hand, due to the popularity of camera phones and the integration of multimedia and IT functions into mobile phones, the transmission volume of the internal signal of mobile phones has increased, and accordingly, there has been a need for modularity.

c) Consumer electronic products. Among consumer products, DSC and DV represent the development of rigid-flex PCBs , which can be considered in two main areas: "performance" and "structure". In terms of performance, the rigid-flex PCB can connect various rigid boards and PCB components in 3D, so the total usable area of the PCB can be increased with the same line density, which can relatively improve its circuit design. capacitance, and reduce the contact signal transmission limit and assembly error rate difference. On the other hand, because the Rigid-Flex PCB is light and thin, it can bend the wiring, which has significant advantages in terms of size and weight reduction.

d) Automobile - the use of rigid-flex circuit board in automobiles , the commonly used buttons connected to the motherboard on the steering wheel, the connection between the car video system screen and the control panel, the working connection of the audio or function keys on the side door and the reverse radar image system, the sensor (including air quality, temperature and humidity, special gas control, etc.), vehicle communication system, satellite navigation, rear seat control panel and front controller connection board, vehicle appearance detection system. , etc.

Advantages of Flexible-rigid Printed Circuit Boards

size and shape , can be adapted to various applications , have better mechanical stability , better performance in harsh environments , are easy to fabricate and test , rigid-flex PCBs are ideal for PCB prototypes.

Frequently Asked Questions:

Q1: Are you a manufacturer of rigid-flex PCB?

A1: Yes, we are Rigid-Flex PCB manufacturer, if you have requirements, we can customize Rigid-Flex PCB for different occasions. Please contact pcb@jbmcpcb.com.

A1: Yes, we are Rigid-Flex PCB manufacturer, if you have requirements, we can customize Rigid-Flex PCB for different occasions. Please contact pcb@jbmcpcb.com.

Hot Tags: Rigid Flex PCB, China, Factory, Manufacturers, Suppliers, Price, Made in China

Related Categories

Send Inquiry

Please feel free to fill your inquiry in the form below. We will reply you in 24 hours.

Related Products

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy