English

English-

English

English -

Español

Español -

Português

Português -

русский

русский -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski

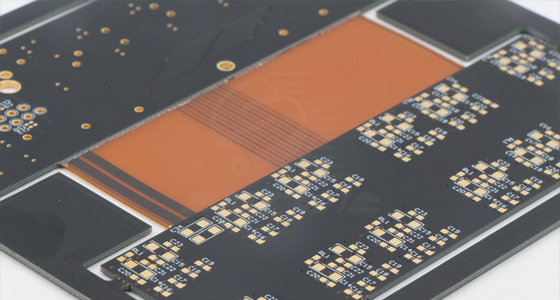

PCB circuit board rapid prototyping service

2025-07-22

In the fast-paced competition of the electronics industry, the speed at which products go from design to market often determines the competitiveness of a company. "PCB circuit board rapid prototyping service" was developed to meet the needs of such rapid iteration and market response. Compared with traditional PCB circuit board prototyping services, it pays more attention to speed and efficiency without sacrificing quality and precision.

The difference between fast proofing service and general proofing service

1. Delivery time: The biggest feature of fast proofing service is fast delivery. Compared with general proofing service, fast service can significantly shorten the delivery time from several days to 24 hours or less by optimizing the production process and improving the response speed of the production line.

2. Production process: Fast proofing service usually adopts more advanced production technology and automated equipment to improve production efficiency and reduce human errors. This process optimization enables the consistency and reliability of products to be maintained even in the case of rapid production.

3. Customer communication: Fast proofing service provides a more efficient customer communication mechanism. Using online platforms and instant messaging tools, customers can track the order status in real time, communicate with the production team in real time, and speed up problem solving.

4. Cost control: Although fast service may involve higher costs, it can bring greater economic benefits to enterprises in the long run by reducing time costs and speeding up product launch.

5. Personalized service: Fast proofing service often provides more personalized service options, such as emergency order processing, special materials or process selection, to meet the special needs of different customers.

6. Quality Assurance: Even while pursuing speed, the rapid prototyping service does not relax the control of product quality. Through a strict quality inspection process, it ensures that each PCB board meets high standards.

In general, the advantage of the rapid prototyping service is that it can quickly respond to market changes and customer needs, and accelerate the transformation of products from concept to prototype. This service is particularly suitable for projects with short R&D cycles and fast market iterations, such as product development of start-ups, prototype testing of R&D teams, and situations where rapid response to market feedback is required.

PCB circuit board rapid prototyping service is an important driving force for the rapid development of the electronics industry. It helps companies shorten product development cycles and accelerate the pace of innovation by providing fast, efficient and personalized services. With the advancement of technology and the continuous changes in market demand, the rapid prototyping service will continue to develop and improve, and make greater contributions to the prosperity of the electronics industry.