English

English-

English

English -

Español

Español -

Português

Português -

русский

русский -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski

High precision PCB circuit board manufacturer

2025-03-28

With the rapid development of the electronics industry today, high-precision PCB circuit boards have become a key factor in promoting technological innovation and product upgrades. As professional manufacturers in this field, they ensure the high precision and high reliability of PCB circuit boards through exquisite craftsmanship and strict quality control. The following will explore in depth the core capabilities, production processes of high-precision PCB circuit board manufacturers and their important role in the electronics industry.

1. Capabilities that high-precision PCB manufacturers usually have

High-precision PCB manufacturers focus on producing circuit boards with fine lines and tiny sizes. These products are important for the functionality and performance of electronic equipment. Manufacturers usually have the following core capabilities:

Advanced design capabilities: High-precision PCB manufacturers have professional design teams that can use advanced design software to carry out high-density circuit layout and design according to customer needs.

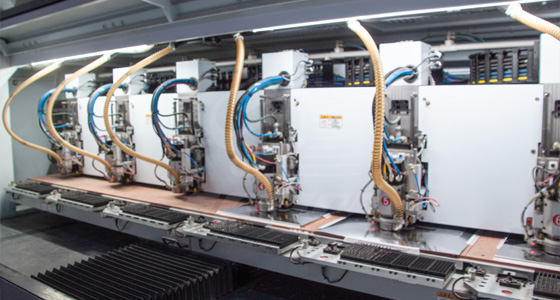

Precision manufacturing process: During the production process, manufacturers use high-precision equipment for key steps such as drilling, exposure, and etching to ensure the accuracy of the circuit and the flatness of the board surface.

Strict quality control: Through the implementation of a comprehensive quality management system, from raw material inspection to final product testing, every link is strictly controlled to ensure that the product meets high standards.

Continuous technological innovation: Manufacturers continue to invest in research and development, explore new materials and new processes to improve the performance of PCB circuit boards and meet the market demand for higher-performance electronic products.

Flexible customization services: According to the special needs of different customers, provide personalized customization services, from design to production, to meet customers' customization requirements in all aspects.

2. What is the production process of high-precision PCB circuit board manufacturers?

Demand analysis: Communicate with customers to accurately understand product requirements and technical indicators.

Raw material preparation: Select appropriate substrate materials and copper foil to ensure material quality.

Manufacturing: Perform fine processing and manufacturing in a highly automated production line.

Quality inspection: Perform multi-dimensional inspection of products, including size, conductivity, etc.

Post-processing: Perform surface treatment and add protective coating according to the product application environment.

Final inspection and shipment: Complete the final inspection to ensure that each product meets the factory standards.

High-precision PCB circuit boards are widely used in communication equipment, medical equipment, high-end servers, aerospace and other fields. They have the function of connecting electronic components and transmitting electrical signals in these devices. As electronic equipment develops towards smaller size and higher performance, the precision requirements for PCB circuit boards are also getting higher and higher.